Matt Hoodmaker Engineering Portfolio

I am a fourth-year mechanical engineering student at California Polytechnic State University in San Luis Obispo, California (Cal Poly). I am deeply interested in designing and creating projects!

I have showcased some of my projects from the clubs I am involved in, as well as personal and school projects that I have worked on.

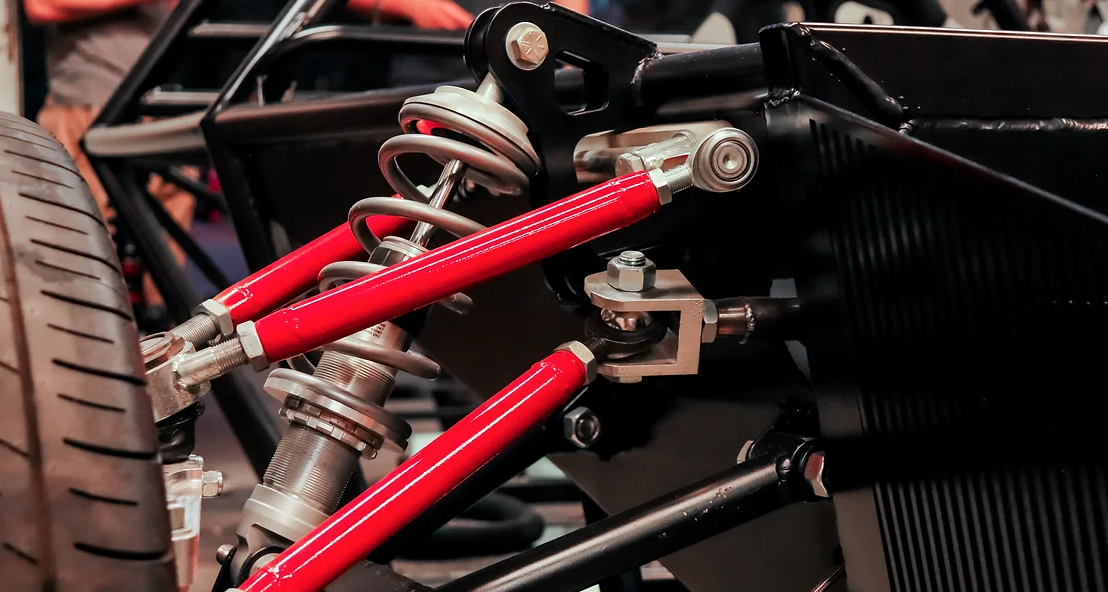

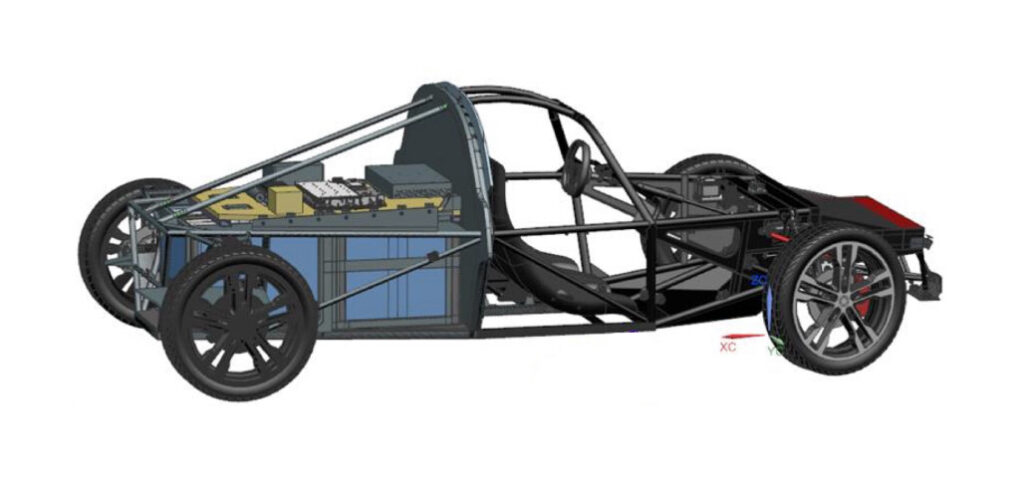

Prototype Vehicles Lab - Project MILA

Last year, I was a member of the Prototype Vehicles Lab (PROVE) at Cal Poly which is a club that aims create a fully electric car with the goal of breaking the Guinness World Record of driving 1000 miles on a single charge. Project MILA will hold over 7000 batteries.

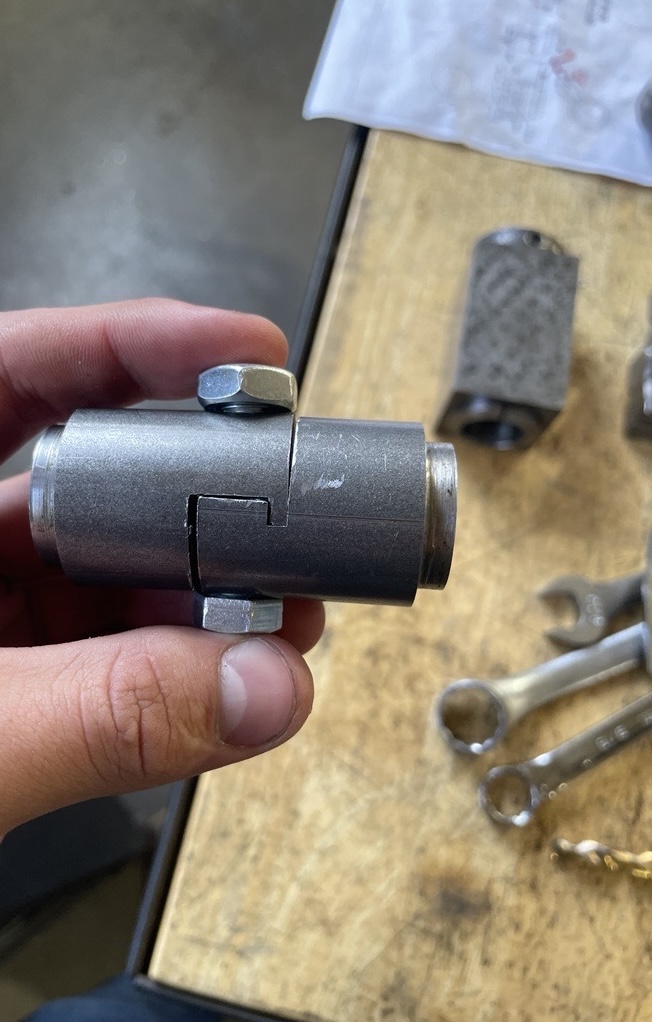

I manufactured and integrated the couplers needed to allow the trunk to be easily opened to access the batteries which are stored in compartments in the trunk.

I also worked closely with the aeroshell team to ensure the coupler design did not interfere with the carbon fiber shell

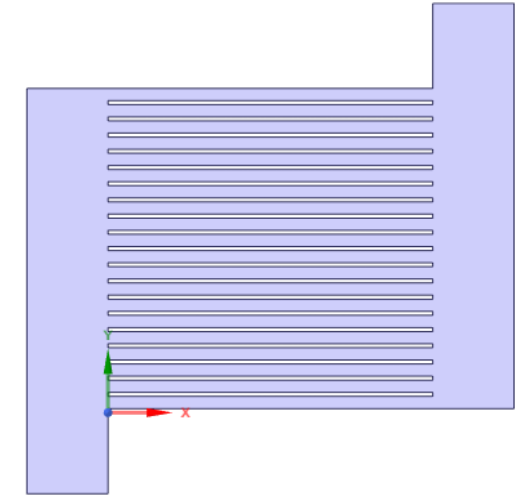

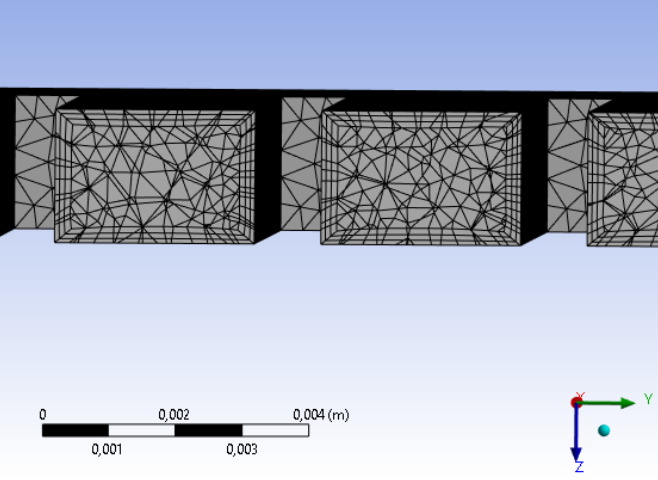

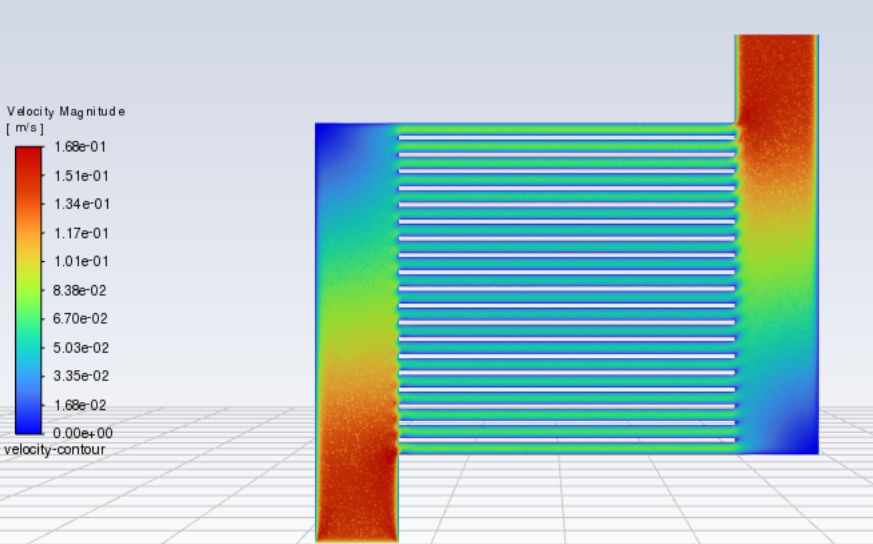

CFD Investigation of Hydrogen Flow Distribution in a Fuel Cell

This summer, I had the opportunity to study abroad in Munich, Germany where I modeled and analyzed the flow of hydrogen in a fuel cell flow field geometry with one inlet and one outlet using ANSYS fluent. I then ran my solution with multiple different velocities to compare the resulting laminar and turbulent regions.

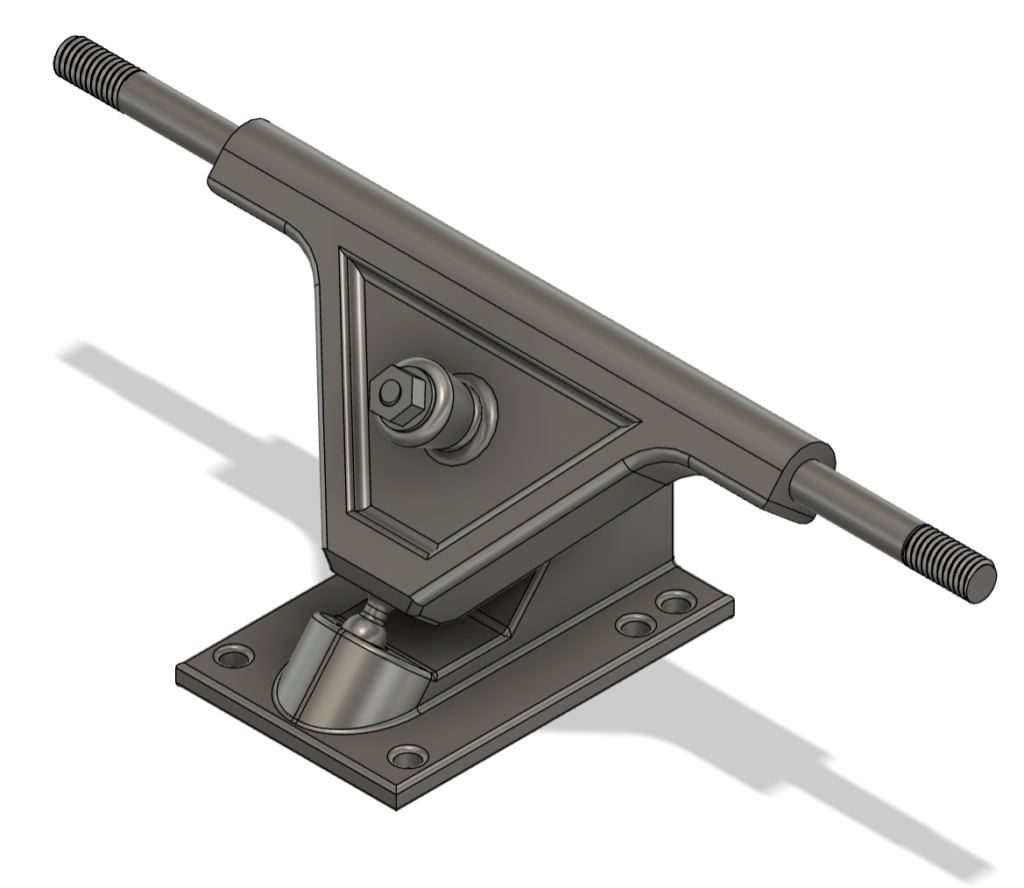

Weight Reduction Trucks

I am building weight reduction trucks for a skateboard with the goal of removing as much weight as possible without impacting the overall strength of the truck itself. I am currently still in the design phase of this project, but as of right now I am hoping to start working on FEA analysis as well as creating some prototypes using a lathe and mill. I am designing this product to withstand 180 pounds of force with a factor of safety of about 2.2.

In order to remove weight from the trucks, I plan on making fillets and chamfers in my design. Preventing sharp edges will minimize stress concentrations while promoting weight reduction in my part. After using FEA analysis, I will modify my design as needed.

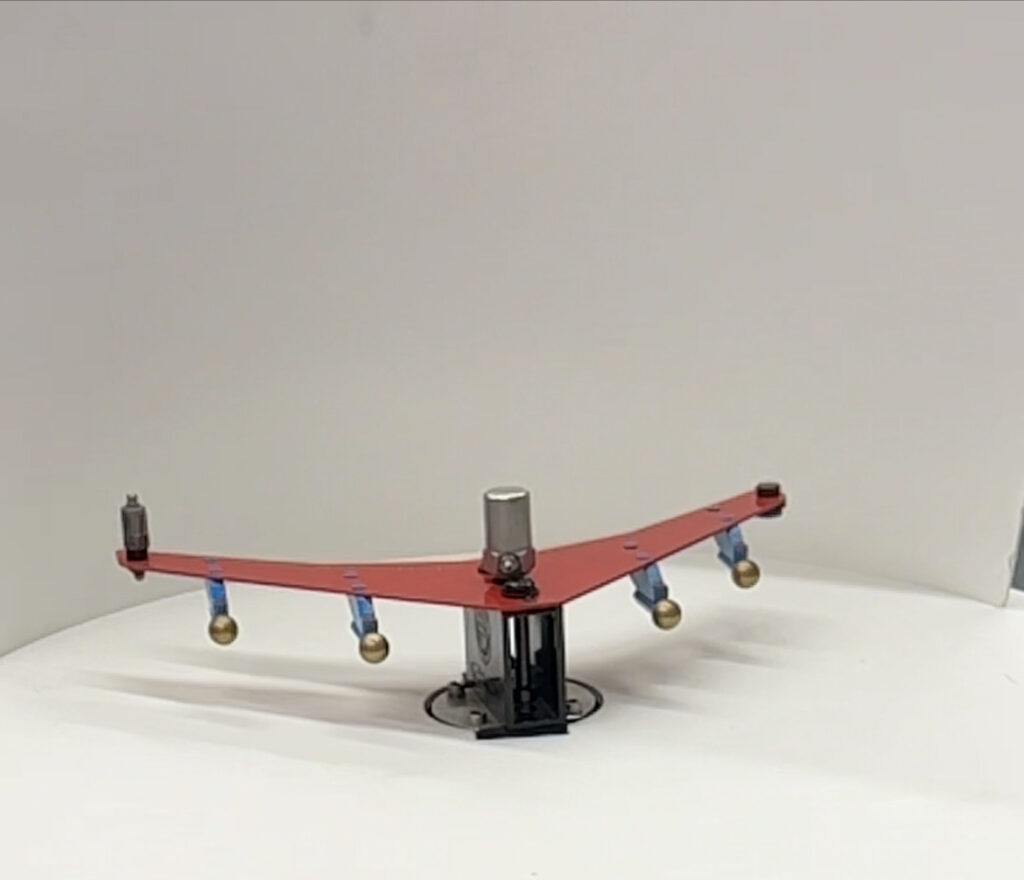

Rotational Imbalance Machine

I designed and tested a machine that allows the user to directly view the amount of rotational imbalance on the cantilever beam shown on the right. The cantilever beam’s length can be adjusted using a series of screws, and the amount of rotational imbalance can also be adjusted by removing and adding weights onto the motor at the end of the beam.

The weights I used for this project were bolts that were secured to the motor with nuts. When all four bolts are added onto the motor, there will be no rotational imbalance present. As the bolts next to each other are removed, the amount of rotational imbalance increases. This motor would then be attached to an Arduino controller, where the speed can be easily changed.

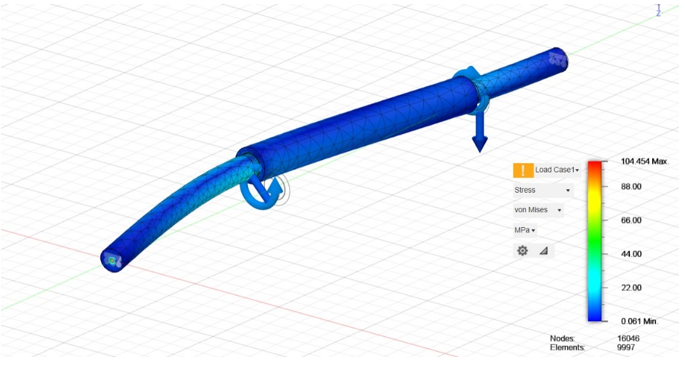

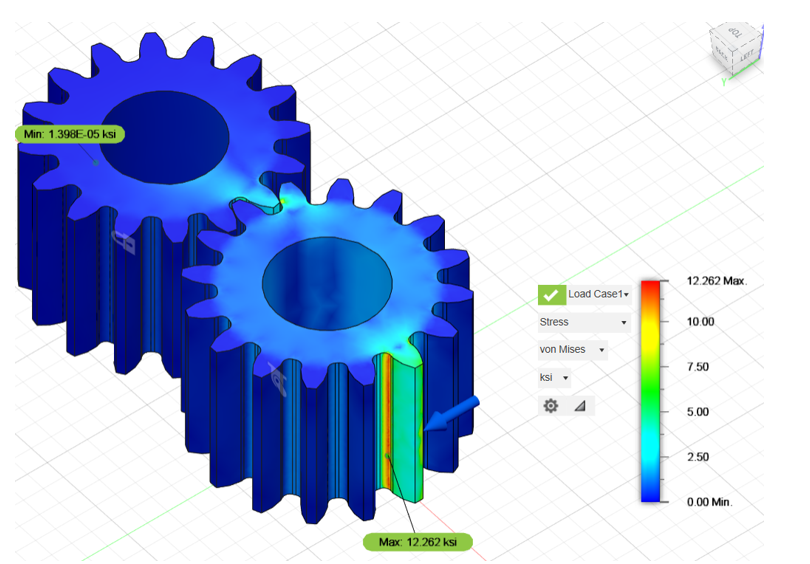

I have also been using FEA analysis to test the effects of different loading conditions on sites such as SolidWorks, Fusion 360, and ANSYS.

Engineering Drawings

At Cal Poly, I have spent a significant amount of time designing many intricate parts using CAD/CAM products and created detailed engineering drawings from these parts with an emphasis on GD&T.

A video of a bottling station that I designed and assembled using CAD for one of my courses at Cal Poly